CIRCUMET

Advanced School on Circular Metal Components for the Swedish Manufacturing Industry

Upcoming webinar:

March 20, 2026; 11:00-12:00: Industry 5.0: Human-Centric Manufacturing (Register here External link, opens in new window.)

This webinar introduces Industry 5.0 and how manufacturing organisations can combine automation and data‑driven processes with a stronger focus on human‑centricity, resilience, and sustainability. You will gain insight into how technologies such as digital twins, AR/VR, and robots/cobots enable this transition in practice. The session is led by Benedikt Neyses, Researcher in Applied AI at RISE Research Institutes of Sweden, with extensive experience in AI, machine learning, and digitalisation in manufacturing. Benedikt brings both academic depth and strong industry relevance from his work with production and manufacturing transition.

CIRCUMET aims at creating a comprehensive joint effort for developing 80-90 credits courses in advanced level on the topic of climate action in the metal component manufacturing industry. Flexible pedagogical methods and tailored admission routines will be developed for attracting professionals from the industry.

Frequently Asked Questions about applying to the CIRCUMET Courses

Do all CIRCUMET courses have the same entry requirements?

No, the entry requirements may vary, so always refer to the specific course information on the website.

If I have extensive professional experience in the course area, can I apply even if I haven’t previously studied at university level or in the relevant field?

- For courses offered by JU and HV, you may be eligible for CIRCUMET courses if you have at least four years of relevant work experience, which will be assessed based on a submitted employment certificate. Use the certificate template available down below.

- For courses at Chalmers, an academic degree is required for eligibility. However, you can apply through a process called validation of prior learning. In this case, a combined assessment of your professional experience and previous education will determine whether you are likely to succeed in the course. Contact Chalmers for more information.

Do I need to attach any other documents when I submit my application?

- It depends. If you studied at a Swedish university before 1995 or hold a foreign degree, you will need to upload your certificates on antagning.se, unless you’ve done so previously.

- To prove your English proficiency, it may also be necessary to upload your upper secondary school certificate if it was issued before 2005. You may also demonstrate your English skills via an employment certificate that shows you’ve used English professionally.

- If work experience is required as part of the entry criteria, you must verify this with an employment certificate. See the template down below.

Who can I contact if I have questions about the application process or validation for CIRCUMET courses?

- Jönköping University:

lifelonglearning@ju.se or lina.acosta@ju.se - Chalmers University of Technology:

christer.marklund@chalmers.se - University West:

antagning@hv.se

Courses offered by Chalmers University of Technology:

- Joining for Disassembly

- Cast Component Design for Rcyclability

- Weld Design for Sustainability

- Metallic Material Development for Circularity and Future Trends – Ferrous Alloys

- Metallic Material Development for Circularity and Future Trends – Non-Ferrous Alloys

- Metallic Material Development for Circularity and Future Trends – Sustainability Aspects

Courses offered by University West:

- Industry 4.0 - Emerging Technologies

- Industry 5.0 - Human-centric Metal Manufacturing

- Joining Processes for a Modern and Sustainable Manufacturing Industry

Courses offered by Jönköping University:

- Circular Metal Supply Chain

- Science of Remelting – Aluminium Alloys

- Science of Remelting – Ferrous Alloys

You’ll find the employment certificate template for applications to Jönköping University and University West here docx, 47.6 kB, opens in new window.. Upload it under "Mina meriter" on antagning.se when submitting your application.

You can also find more FAQs (in Swedish) at: https://www.antagning.se/sv/vanliga-fragor-och-svar/

Courses starting Spring 2026

Weld Design for Sustainability, 2.5 credits, Chalmers

Weld Design for Sustainability, 2.5 credits

Smarter welds, greener future?

Learn to design welded components and structures that are strong, sustainable, and efficient. This course combines weld design principles based on international standards with awareness on durability, resource efficiency, and circularity. You’ll explore welding processes, their physics, and key non-destructive testing (NDT) methods, while building the skills to assess welds and make informed design choices for quality and sustainability.

Cast Component Design for Recyclability, 2.5 credits, Chalmers

Cast Component Design for Recyclability, 2.5 credits

Design castings for a sustainable tomorrow!

Casting is one of the most widely used manufacturing routes, but how we design cast components today will determine their recyclability and value in tomorrow’s circular economy. This course gives you the tools to make smarter material and process choices, optimize component geometry, and apply design-for-recycling principles that enhance both performance and sustainability. With case studies, industry insights, and practical design methods, you will learn how to turn recyclability into a driver of innovation and competitiveness in casting.

Industry 4.0 - Emerging Technologies, 2.5 credits, University West

Industry 4.0 - Emerging Technologies, 2.5 credits

Elevate your career with our Industry 4.0 course, tailored for professionals ready to lead the digital manufacturing revolution. Explore the shift from mechanization to smart systems, mastering technologies like Virtual Factory, Digital Twins, IoT, Big Data, and AI. Learn cybersecurity essentials and analyze real-world case studies to identify improvement opportunities. Combining theory and practical exercises, this course prepares you for roles in manufacturing engineering, digital transformation, and technology implementation. Enroll now to drive innovation.

Read more and apply here! External link, opens in new window.

Industry 5.0 - Human-centric Metal Manufacturing, 2.5 credits, University West

Industry 5.0 - Human-centric Metal Manufacturing, 2.5 credits

Industry 4.0 (I4.0) is transforming manufacturing through digital technologies and enhanced process efficiency, impacting the entire supply chain. Implementation challenges require consideration of people, management, structure, and culture. In response, Industry 5.0 (I5.0) has emerged, emphasizing sustainable, human-centered perspectives. I5.0 complements I4.0 by integrating human skills with advanced technologies, fostering a symbiotic relationship between humans and machines, and promoting value creation and resilience.

PS. Don't miss the webinar mentioned above!

Read more and apply here! External link, opens in new window.

Joining for Disassembly, 2.5 credits, Chalmers. Closed for application

Joining for Disassembly 2.5 credits

Joining Methods for Sustainable Design and Reuse

Joining isn’t just about holding things together; it’s about shaping how we design, reuse, and recycle. This course explores joining techniques that support circular design and material reuse. Focusing on non-fusion methods like adhesive bonding, mechanical joining, and brazing, you will examine how joining choices impact performance, recyclability, cost, and disassembly. The course builds a real-world approach to selecting methods based on material properties, mechanical demands, and environmental impact.

Closed for application.

Circular Metal Supply Chains, 5 credits, JTH. Closed for application

Circular Metal Supply Chains, 5 credits

From Linear to Circular: Master the Metal Supply Chain

This course explores how the transition toward a circular economy is transforming purchasing and supply functions in the metals industry. The course provides practical insights into digital product passports, life cycle analysis, and the role of purchasing in building sustainable and competitive business models. You will develop skills to compare materials and suppliers from a sustainability perspective, improve communication across organizational and supply chain boundaries, and understand how legislation, customer demands, and new production technologies influence supply chains. Designed for professionals in purchasing, logistics, or supply chain management, the course combines theory and practice in English.

Courses in Autumn 2025

Science of Remelting - Aluminium Alloys, 2.5 credits, JTH

Science of Remelting - Aluminium Alloys, 2.5 credits

Drive innovation in aluminium recycling and sustainability!

This course is your gateway to mastering the science behind lightweight, corrosion-resistant, and endlessly recyclable aluminium—an essential material in automotive and aerospace industries. Learn to optimize remelting processes, control impurities with precision, and enhance alloy quality, all while reducing environmental impact. With the growing demand for sustainable, high-quality recycled materials, this course equips you with the skills to lead the way in transforming aluminium production for a greener future.

Metallic Material Development for Circularity and Future Trends – Non-ferrous alloys, 2.5 credits, Chalmers

Metallic Material Development for Circularity and Future Trends – Non-ferrous alloys, 2.5 credits

Designing Alloys for a Circular Future

Can non-ferrous alloys become truly sustainable? This course explores aluminium, magnesium, titanium, and nickel-based alloys, focusing on their recycling potential and innovative design for circularity. Learn to critically evaluate sustainability challenges, assess secondary feedstock strategies, and explore cutting-edge research on alloy development. Gain the skills to shape a more resilient and resource-efficient future.

Metallic Material Development for Circularity and Future Trends – Ferrous alloys, 2.5 credits, Chalmers

Metallic Material Development for Circularity and Future Trends – Ferrous alloys, 2.5 credits

Sustainable Steel: Designing Ferrous Alloys for a Circular Future

Ferrous alloys are key to the green transition—but how can we make them truly sustainable? This course explores strategies for life-time extension, recycling, and lean composition steel design. Learn to use Thermo-Calc for predicting phase formations in recycled steels and critically assess cutting-edge solutions for circular alloy development. Gain the expertise to drive sustainable innovation in the steel industry.

Joining Processes for a Modern and Sustainable Manufacturing Industry, 2.5 credits, University West

Joining Processes for a Modern and Sustainable Manufacturing Industry, 2.5 credits

Material Joining for a Sustainable Future

Enhance your expertise in modern welding with a focus on sustainability, quality, and productivity. This course explores advanced arc welding processes like CMT, STT, and TIG DynamicWire, as well as multi-material joining in the automotive industry. Learn to optimize welding parameters, reduce waste, and improve efficiency through cutting-edge techniques. Engage in interactive discussions and apply your knowledge directly to real-world challenges.

Courses to be developed

- Foundations of Data-driven Thinking, prel. start September 2026

- Design of Experiments, prel. start October 2026

- Energy & Resource Afficient Additive Manufacturing, prel. start October 2026

- Quality Process Control in Metal Component Manufacturing, prel. start November 2026

- Machine Learning and AI in Manufacturing, prel. start November 2026

Latest news:

- January 15, the CIRCUMET project consortium held a half-year annual meeting at Sanvik Coromant in Gimo planning courses for Autumn -26 and Spring -27.

- Courses for Spring 2026 opens for applications in mid-October.

What happens next?

%20Circumet%20timeline.png)

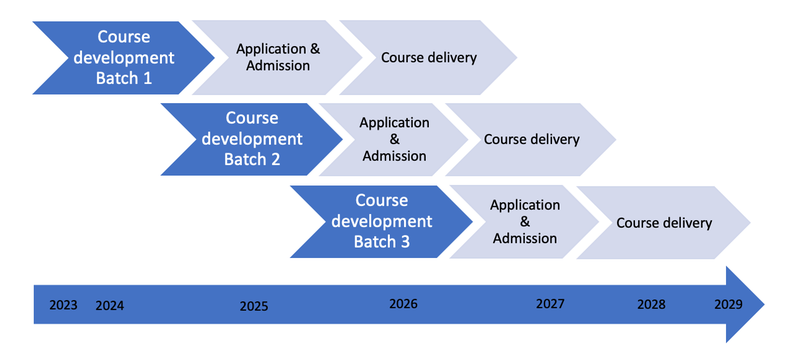

In late 2023 and during 2024 courses will be decided, and planned, and the first batch of courses will start to be developed. The first batch of courses open for application will be released in spring 2025, and those courses will start in autumn 2025. Since we are at an early stage of the project, course format, application procedures and prerequisites are not yet set.

But do sign up above to receive information as soon as such is posted.

The CIRCUMET plan

Objective

- Create a joint effort for developing 80-90 credits courses at advanced level on the topic of climate action in the metal component manufacturing industry.

- Develop flexible pedagogical methods, and innovative admission/validation routines for effective competence supply for the professionals in the industry.

- Pilot-run the developed courses and accordingly fine-tune the methodologies and contents if needed.

- Plan and develop the industrial research school proposal on the climate action for the metal industry.

Importance of the project

Particularly in Sweden, the manufacturing industry is considered the backbone of the economy, with more than 13% contribution to the GDP, and the metal component manufacturing industry is among the top sectors. Yet manufacturing sector has an outsized impact on the environment with around 20-25% direct CO2 emissions.

On the other hand, there are very limited and, in most cases, scattered educational packages related to climate action in the metal component manufacturing industry. This highlights the urgency and importance of developing tailored and flexible competence supply in both academia and industry, in order to effectively fight against climate change in the metal component manufacturing sector.

Expected results

The effort covers the circularity and sustainability in the entire value chain of metal component manufacturing; from component design optimization, to manufacturing processes, material selection, and even after the component lifetime. Important topics such as Digitalization, Life cycle analysis, and Business models in circular metal component manufacturing are embedded within the project scope.

This is in-line with many industrial sectors’ commitment to the business ambition for a 1.5˚C goal, which targets a climate-neutral and circular business by 2040. The Swedish “Riksdag” also has a clear goal in this regard: by latest 2045, Sweden must have no net emission of greenhouse gasses to subsequently achieve negative emissions.

Project team

Financier: KK-Stiftelsen External link, opens in new window.

Duration of the project: 2023-2029

Management team:

Ehsan Ghassemali, Assoc. Prof. JTH

Johan Ahlström External link, opens in new window., Prof. Chalmers

Madelene Zetterlind, Pedagogical developer, JTH

Stefan Brolin External link, opens in new window., External relations, JTH

Industrial Partners:

GKN Aerospace Sweden, Sandvik Coromant, Fagerhult, Husqvarna Group, Scania CV, Volvo Cars, Comptech, AGES Industri, Ovako, Stena Metal International, Gjuteriföreningen, Jernkontoret, Svenskt Aluminium, Tunga Fordon, Fordonskomponentgruppen

Contact us

We would be glad to hear your opinion and suggestions:

For specific questions about applications and eligibility, send a mail to: LLL@ju.se

Project leader: Ehsan Ghassemali

Deputy leader: Johan Ahlström (Chalmers) External link, opens in new window.

Pedagogcal developer: Madelene Zetterlind External link, opens in new window.

Marketing and communication: Stefan Brolin, Linda Bergqvist Opens in new window.

Text

Text

Text