Mechanical Testing

Our mechanical testing lab offers in-depth insights into material performance across a range of loading conditions. This vital knowledge enables the optimization of both materials and processes, ensuring that you achieve the highest level of performance and reliability.

Hardness

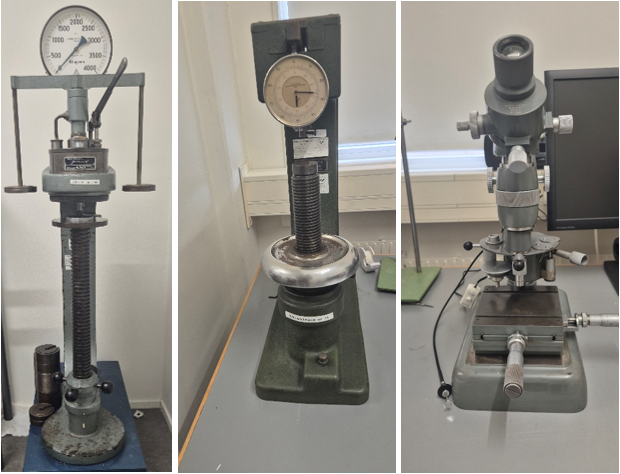

Hardness tester Brinell

> Supplier: AB Alpha

> Testing methods: Brinell.

> Type of material for testing: Metals.

> Load on the ball: 62,5 kg, 250 kg, 500 kg, 3000 kg

> Ball indenter diameter: 10 mm or 5 mm.

> Indenter material: Tungsten carbide.

> Temperature range: Room temperature.

Hardness tester: Vickers and Rockwell

> Supplier & Model: AB Alpha, Durometer

> Testing methods: Vickers 20 kg and 30 kg.

Rockwell A, Rockwell B, Rockwell C.

> Type of material for testing: Metals.

> Load on the indenter: Vickers 20 or 30 kg.

Rockwell 60 kg, 100 kg, 150 kg.

> Indenter material: Tungsten carbide ball or diamond cone.

> Temperature range: Room temperature.

Hardness tester Micro Vickers.

> Supplier: E. Leitzer

> Testing methods: Micro Vickers.

> Type of material for testing: Metals.

> Load on the indenter: 25 g, 50 g, 100 g, 200 g, 300 g, 500 g.

> Temperature range: Room temperature.

> Reading in a separate digital microscope.

Micro/Nano Hardness

Capable of micro and nano indentation testing; Micro and nano scratch/wear testing

- Supplier & Model: Micro Materials; NanoTest Vantage 4

- Type of Material for testing: all

- Testing methods: Intentation (Vickers & Bercovich), Scratch, Pin-on-Disc

- Temperature range: RT

- Load capacity: Nanoindentation: 0.5-500 mN; Microindentation: 500 mN - 20 N

- Other: Acustic emission and friction measurements

Tensile/Compression/Creep (universal)

Universal testing machine capable of low and high temperature tensile testing, compression testing and creep testing.

- Supplier & Model: Zwick/Roell100

- Type of Material for testing: all

- Testing methods: Tensile, Compression, Creep

- Temperature range: RT to 1000°C for tensile and creep (resistance furnace); RT to 500°C for compression

- Loadcell: ±100kN, ±20kN, ±5kN

- Extensometer: 20 mm contact; RT and high temp

In addition to this, we have an in-house built creep testing instrument (constant load) for testing up to ~500°C.

There is alos a Lloyd EZ50 tensile/compression/creep instrument with a climate chamber for subzero and environmental mechanical testing.

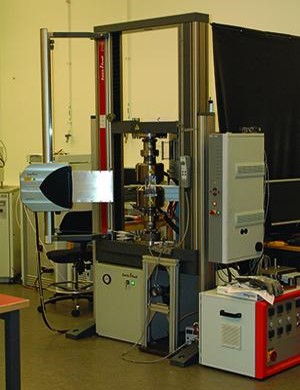

Fatigue

Capable of conducting variety of Fatigue testing methods

- Supplier & Model: MTS - 370.25 Load Frame

- Type of Material for testing: all

- Testing methods: Fatigue, Tensile

- Temperature range: RT to 1100°C (resistance furnace)

- Loadcell: ±250kN, ±10kN, ±2.5kN

- Extensometer: 25, 50 mm and High-temp extensometer, Wedge-grips for flat and round specimen

Charpy/Impact

Charpy method. Our impact rig measures impact toughness, i.e. the amount of energy the material absorbs during fracture. The experiments are very quick and easy to execute, which makes it ideal for studying temperature-dependent ductile-brittle transition.

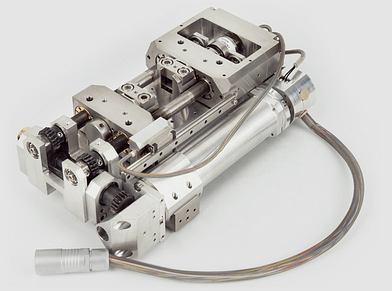

In-situ mechanical testing

In-situ stage

- Supplier & Model: Kammrath & Weiss / 5kN module

- Type of Material for testing: all

- Testing methods: Tensile/Compression/Cyclic loading for up to 5 kN loading, up to 20 um/s withdrwal rate

- Temperature range: RT up to 800C

- Compatible for in-situ EBSD testing (tilted)